Dans Usinage CNC, des changements d'outils fréquents sont nécessaires pour gérer diverses opérations. Les changements d'outils manuels augmentent les temps d'arrêt et les risques d'erreurs qui compromettent la précision et la productivité. Cette inefficacité devient un obstacle important dans les industries qui dépendent de processus de fabrication précis et à grande vitesse.

Le changeur d'outils automatique CNC offre une solution en automatisant de manière transparente les échanges d'outils. Il élimine les interventions manuelles, rationalise les flux de travail et garantit une manipulation précise des outils. Cette technologie améliore l'efficacité, réduit les temps de configuration et permet aux machines de fonctionner en continu sans interruption. Le résultat est une productivité opérationnelle améliorée et une qualité de production constante, répondant aux exigences de la fabrication moderne.

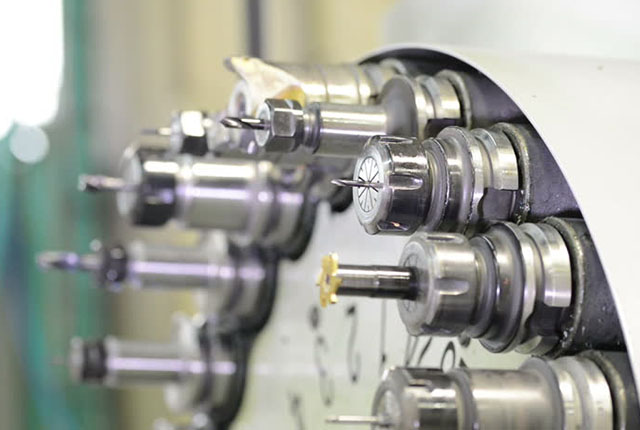

Un changeur d'outils automatique CNC comprend plusieurs pièces essentielles qui fonctionnent ensemble pour automatiser les changements d'outils.

Base

La base est la pièce fondamentale qui supporte l’ensemble du mécanisme de changement d’outil. Il assure la stabilité et garantit un alignement précis lors des changements d'outils, réduisant ainsi le risque d'erreurs.

Le magasin d'outils est l'endroit où les outils sont stockés lorsqu'ils ne sont pas utilisés. Il existe dans diverses configurations, telles que des types de carrousel ou de chaîne, et contient plusieurs outils. La capacité dépend de l'application et de la conception de la machine.

Le bras de préhension gère l'échange proprement dit des outils. Il est conçu pour récupérer rapidement et précisément les outils du magasin et les insérer dans la broche.

Les porte-outils sécurisent les outils pendant le fonctionnement et le transport dans le système. Ils doivent assurer une prise ferme pour éviter de glisser, notamment lors d'usinages à grande vitesse.

Le système de contrôle intègre le changeur d'outils à la machine CNC. Il coordonne le processus de sélection des outils, garantissant des transitions d'outils fluides et précises basées sur des instructions programmées.

Chaque élément contribue au bon fonctionnement du Changeur d'outils automatique CNC, garantissant des temps d'arrêt minimaux et une productivité optimale.

Différents changeurs d'outils automatiques CNC sont conçus pour répondre à diverses exigences d'usinage.

Les ATC à tambour ont une conception compacte et circulaire et sont couramment utilisés dans les petites machines. Ils permettent des changements d'outils rapides pour les machines nécessitant des capacités d'outils modérées.

Les ATC de type chaîne utilisent un mécanisme de chaîne pour contenir les outils, offrant ainsi une capacité de stockage d'outils plus élevée. Ceux-ci conviennent aux machines plus grandes et aux applications nécessitant de nombreux outils.

Les ATC de type tourelle ont une tourelle rotative qui contient des outils. Ce type est idéal pour les applications nécessitant des changements d'outils fréquents avec un positionnement précis.

Les ATC de type en ligne sont souvent utilisés dans des configurations plus simples. Ils ont une disposition linéaire des outils et sont conçus pour des machines moins complexes.

Taper | Capacité de l'outil | Applications | Avantages | Limites |

Type de tambour | Faible à modéré | Usinage à petite échelle, installations compactes | Changement d'outil rapide, taille compacte | Capacité d'outil limitée |

Type de chaîne | Haut | Usinage à grande échelle, besoins en outils diversifiés | Prend en charge de nombreux outils, polyvalent | Nécessite plus d'espace |

Type tourelle | Modéré | Opérations axées sur la précision | Précis et fiable | Changements d'outils plus lents |

Type en ligne | Faible | Systèmes simples et compacts | Intégration facile et rentable | Limité aux opérations de base |

Le changeur d'outils automatique CNC suit un processus systématique pour changer d'outil efficacement pendant l'usinage.

Le système de contrôle identifie l'outil requis en fonction des instructions programmées. Le système fait ensuite pivoter le magasin d'outils ou positionne la ligne de l'outil pour y accéder.

La broche se déplace vers la position de changement d'outil. Le bras de préhension s'aligne avec l'outil dans le magasin pour garantir un échange précis.

Le bras de préhension retire l'outil actuel de la broche. Cette étape nécessite de la précision pour éviter d'endommager l'outil ou la broche.

Le bras robotique récupère le nouvel outil dans le magasin et l'ajoute à la broche. Des capteurs et des actionneurs garantissent que l'outil est bien verrouillé en place.

Le système vérifie que le bon outil est installé et sécurisé. Si des erreurs sont détectées, la machine s'arrête pour éviter des problèmes de fonctionnement.

Les changeurs d'outils automatiques CNC sont cruciaux dans diverses industries, prenant en charge divers processus de fabrication.

Les machines CNC équipées de changeurs d'outils automatiques sont utilisées pour les tâches de fraisage, de tournage et de perçage dans le travail des métaux. Ces machines améliorent l'efficacité en automatisant le passage d'un outil à l'autre, essentiel pour usiner des pièces métalliques complexes avec une haute précision.

Les routeurs CNC avec changeurs d'outils automatiques sont largement utilisés dans l'industrie du bois. Ils gèrent des tâches complexes de découpe, de gravure et de sculpture, permettant des transitions fluides entre les types d'outils. Cela garantit des finitions de haute qualité dans les armoires, les meubles et les objets de décoration.

Les fabricants travaillant avec des plastiques et des matériaux composites utilisent des machines CNC avec ATC pour la découpe et le façonnage. Le processus automatisé améliore la cohérence, en particulier dans la production de composants légers et durables pour l’aérospatiale, l’automobile et les biens de consommation.

Les changeurs d'outils automatiques CNC rationalisent les processus de prototypage en permettant d'effectuer plusieurs opérations sur une seule machine. Ceci est bénéfique pour le prototypage rapide et la production en petits lots, où le temps est critique.

Dans le secteur de la fabrication à grand volume, les ATC réduisent les temps d'arrêt et augmentent les cadences de production. Des industries telles que l’électronique, l’automobile et l’électroménager s’appuient sur cette technologie pour produire efficacement des composants standardisés.

• L'automatisation réduit les temps d'arrêt associés aux changements manuels d'outils.

• Permet aux machines de fonctionner en continu, augmentant ainsi la capacité de production.

• Élimine les erreurs humaines lors des changements d’outils.

• Assure un positionnement cohérent des outils pour un usinage de haute qualité.

• Réduit le temps de configuration en automatisant la sélection et le remplacement des outils.

• Accélère les processus d’usinage complexes nécessitant plusieurs outils.

• Accueille une variété d’outils pour diverses opérations d’usinage.

• Permet une flexibilité dans la gestion de différents matériaux et conceptions.

• Réduit les coûts de main-d’œuvre en minimisant les interventions manuelles.

• Réduit les temps d’arrêt des machines, améliorant ainsi la rentabilité globale.

• S'intègre parfaitement aux systèmes CNC avancés.

• Prend en charge les initiatives de l'Industrie 4.0 en permettant une automatisation basée sur les données.

Assurez-vous que l'ATC est compatible avec votre machine CNC. Le type d’ATC, tel qu’un tambour ou une chaîne, doit correspondre à la taille et à l’application de la machine.

Évaluez la capacité d’outils requise en fonction de vos besoins de production. Pour les opérations à volume élevé, un ATC de type chaîne avec un plus grand stockage d’outils est préférable.

Pensez à modifier la vitesse de l'outil pour minimiser les temps d'arrêt. Des changeurs d'outils plus rapides améliorent la productivité dans les environnements de fabrication où le temps est compté.

Évaluer la complexité et la fréquence de la maintenance de l'ATC. Pour réduire les temps d'arrêt, optez pour des systèmes durables et faciles à entretenir.

Choisissez un ATC adapté aux tâches d'usinage spécifiques. Par exemple, les ATC en ligne fonctionnent bien pour les systèmes compacts, tandis que les ATC de type tourelle conviennent aux applications axées sur la précision.

Au moment de prendre votre décision, équilibrez le coût initial de l'ATC avec ses caractéristiques et ses avantages. Pensez aux économies et à l’efficacité opérationnelles à long terme.

Les changeurs d'outils manuels et automatiques sont deux méthodes couramment utilisées dans l'usinage CNC, chacune offrant des avantages et des limites distincts.

Dans un changeur d'outils manuel, l'opérateur échange physiquement les outils pendant l'usinage. Ce processus nécessite que l'opérateur arrête la machine, retire l'outil actuel et insère le suivant. Bien que cette méthode soit simple et rentable, elle entraîne des temps d'arrêt, réduit la productivité et augmente le risque d'erreur humaine.

Un changeur d'outils automatique, quant à lui, automatise l'ensemble du processus de changement d'outil. La machine CNC est équipée d'un magasin d'outils et le système ATC sélectionne, retire et installe rapidement les outils sans intervention de l'opérateur. Cela réduit considérablement les temps d'arrêt, augmente l'efficacité de l'usinage et garantit une plus grande cohérence et précision.

• Efficacité : les ATC réduisent les temps d'arrêt et permettent aux machines de fonctionner en continu, tandis que les changements d'outils manuels prennent plus de temps et interrompent le processus.

• Précision : les ATC garantissent que les outils sont positionnés avec précision, minimisant ainsi les erreurs, tandis que les changements manuels reposent sur une intervention humaine.

• Coûts de main d'œuvre : les changeurs d'outils manuels nécessitent une plus grande implication de l'opérateur, tandis que les ATC réduisent le besoin de main d'œuvre humaine et permettent des durées de fonctionnement des machines plus longues.

La mise en œuvre de changeurs d'outils automatiques CNC comporte des défis, mais il existe des solutions connues pour résoudre ces problèmes efficacement.

La technologie avancée des changeurs d’outils automatiques CNC augmente l’investissement initial. Ce coût peut constituer un obstacle pour les petites et moyennes entreprises.

Solution : optez pour des systèmes dotés de fonctionnalités évolutives ou explorez des options de financement pour répartir la charge financière dans le temps.

L'utilisation fréquente de changeurs d'outils automatiques peut entraîner une usure nécessitant un entretien régulier. Ignorer cela peut entraîner une réduction des performances et des temps d'arrêt.

Solution : Mettez en œuvre un programme de maintenance préventive pour garantir que les composants sont inspectés et entretenus régulièrement.

Toutes les machines CNC ne sont pas compatibles avec les changeurs d'outils automatiques et la mise à niveau peut nécessiter des ressources supplémentaires.

Solution : Évaluez la compatibilité des machines et choisissez des ATC conçus spécifiquement pour l’équipement utilisé.

L’exploitation d’un ATC nécessite un personnel qualifié pour gérer le système efficacement. Sans formation appropriée, des erreurs de programmation ou de configuration peuvent survenir.

Solution : Proposer une formation complète aux opérateurs et intégrer des interfaces conviviales pour minimiser la complexité.

Certains modèles ATC peuvent restreindre le nombre d'outils qu'ils peuvent gérer, limitant ainsi leurs applications.

Solution : sélectionnez un ATC dont la capacité correspond aux exigences opérationnelles ou explorez les options modulaires d'expansion.

Les changeurs d'outils automatiques CNC sont essentiels dans les environnements de production à haut volume, où l'efficacité et la rapidité sont essentielles. Ces systèmes automatisent le processus de changement d'outil, réduisant ainsi les temps d'arrêt et garantissant un fonctionnement continu. Dans des entreprises comme la fabrication automobile et électronique, où de grandes quantités de pièces sont produites, la possibilité de changer d'outils rapidement et avec précision permet des cycles de production plus rapides. Les changeurs d'outils automatiques améliorent également la cohérence et la précision, garantissant que chaque pièce répond aux spécifications requises.

Les progrès en matière d’automatisation et de fabrication intelligente façonnent l’avenir des changeurs d’outils automatiques CNC. Les technologies émergentes telles que l'IoT et l'IA amélioreront les capacités des ATC en permettant une maintenance prédictive et une surveillance en temps réel.

Des conceptions plus petites et plus efficaces s'adapteront aux machines CNC compactes, rendant les ATC accessibles à un plus large éventail d'industries. De plus, l’accent accru mis sur l’efficacité énergétique favorisera le développement de systèmes respectueux de l’environnement qui consomment moins d’énergie pendant leur fonctionnement.

L'intégration avec les cadres de l'Industrie 4.0 optimisera la production en permettant aux ATC d'interagir de manière transparente avec d'autres systèmes de fabrication intelligents. À mesure que les industries exigent une plus grande flexibilité, les ATC adaptatifs capables de gérer divers outils et tâches d’usinage gagneront en popularité.

Les changeurs d'outils automatiques CNC ont révolutionné le processus de fabrication en automatisant la gestion des outils. Ils permettent de gagner du temps, de réduire les erreurs et d’améliorer la productivité dans divers secteurs. Relever des défis tels que le coût et la maintenance garantit un fonctionnement efficace, tandis que les progrès technologiques promettent un potentiel encore plus grand.

Les ATC sont essentiels pour la fabrication moderne car ils rationalisent les opérations et permettent un usinage précis. À mesure que les industries évoluent, l'adoption des changeurs d'outils automatiques CNC continuera de croître, soutenant l'innovation et la productivité.

Un changeur d'outils automatique CNC automatise le changement d'outil pendant l'usinage, réduisant ainsi les temps d'arrêt et augmentant l'efficacité.

Il utilise un mécanisme programmé pour sélectionner, récupérer et échanger les outils d'un magasin d'outils vers la broche de la machine.

Les modèles à tambour, à chaîne, à tourelle et en ligne sont les plus courants, chacun étant conçu pour des applications spécifiques.

Il améliore la productivité, améliore la précision, réduit l'effort manuel et prend en charge l'usinage continu.